As Owners and Designers have moved to construct higher performing, more energy efficient buildings, a holistic understanding of how a structure behaves has become paramount to predicting how the building will actually perform. Building Science Consulting is the intellectual and practical examination of a structure as a comprehensive system, considering how each individual assembly or sub-system (HVAC, building envelope, etc.) affects others within the structure. Because most post-occupancy issues are moisture related and occur in the building envelope, Building Science Consulting most often comes into play when examining a heat, air, or moisture transfer issue in the building envelope, and WDP leads the industry in our understanding and experience with Building Science Consulting.

WDP staff are trained to view structures as interconnected systems and to evaluate whether a prescriptive repair to an issue is the most appropriate response, potentially enabling Owners to avoid costly repair mistakes. Our staff are engaged in independent research projects and industry groups which have provided a deeper understanding of why specific criteria are included in codes and standards as well as understanding the behavior and impact of different material properties.

WDP staff have intimate knowledge of various tools that are used to aid in the evaluation of a structure from a building science perspective. These tools are outlined in the sections below.

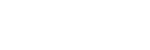

One tool of particular note is hygrothermal analysis – the study of the simultaneous heat and moisture transport within wall assemblies, which is now a code-required evaluation if vapor retarders are to be used in certain Climate Zones. WDP routinely performs both transient and steady state hygrothermal analysis. We use WUFI Pro by Fraunhofer Institute to conduct the transient analysis and either hand calculations, internally developed spreadsheets, or the Heat, Air and Moisture (HAM) toolbox by Quirouette Building Science. Our analysis is generally conducted in accordance with ASHRAE 160 “Criteria for Moisture-Control Design and Analysis in Buildings” and ASHRAE Fundamentals.

When acting either as the Designer of Record or a consultant, WDP typically models proposed wall and roof assemblies to assess the potential risks. Hygrothermal analysis is a critical tool when designing these assemblies for energy efficient buildings or retrofits. This analysis simultaneously models the movement of heat and moisture across the assembly, allowing moisture levels within building components to be simulated. When the results are predicted to be unfavorable, our staff are experienced at running iterative analyses to determine the recommended thermal resistance and vapor permeance properties of the materials used in the wall or roof assembly to produce the most favorable performance.

Like any modeling software, the interpretation of the results of such an analysis is only as good as the assumptions that were made for the initial inputs and having the experience to evaluate the outputs. Using data acquisition as discussed below, WDP staff are able to collect information to calibrate hygrothermal models to verify the outputs are representative of the actual conditions when using hygrothermal analysis to evaluate existing buildings to determine the root cause of problems or alterations to an existing wall for optimal performance or energy improvements. WDP staff also regularly engage with the software developers of WUFI Pro to troubleshoot model outputs that do not align with our expectations based on experience. This engagement has allowed WDP staff to further our understanding of how the software tool is used and adapt modeling techniques to better represent actual conditions for a modeled assembly.

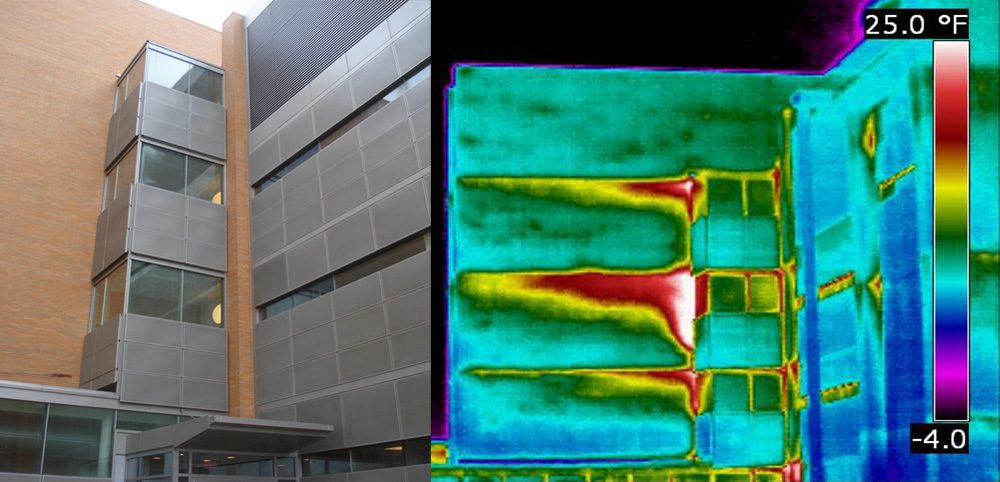

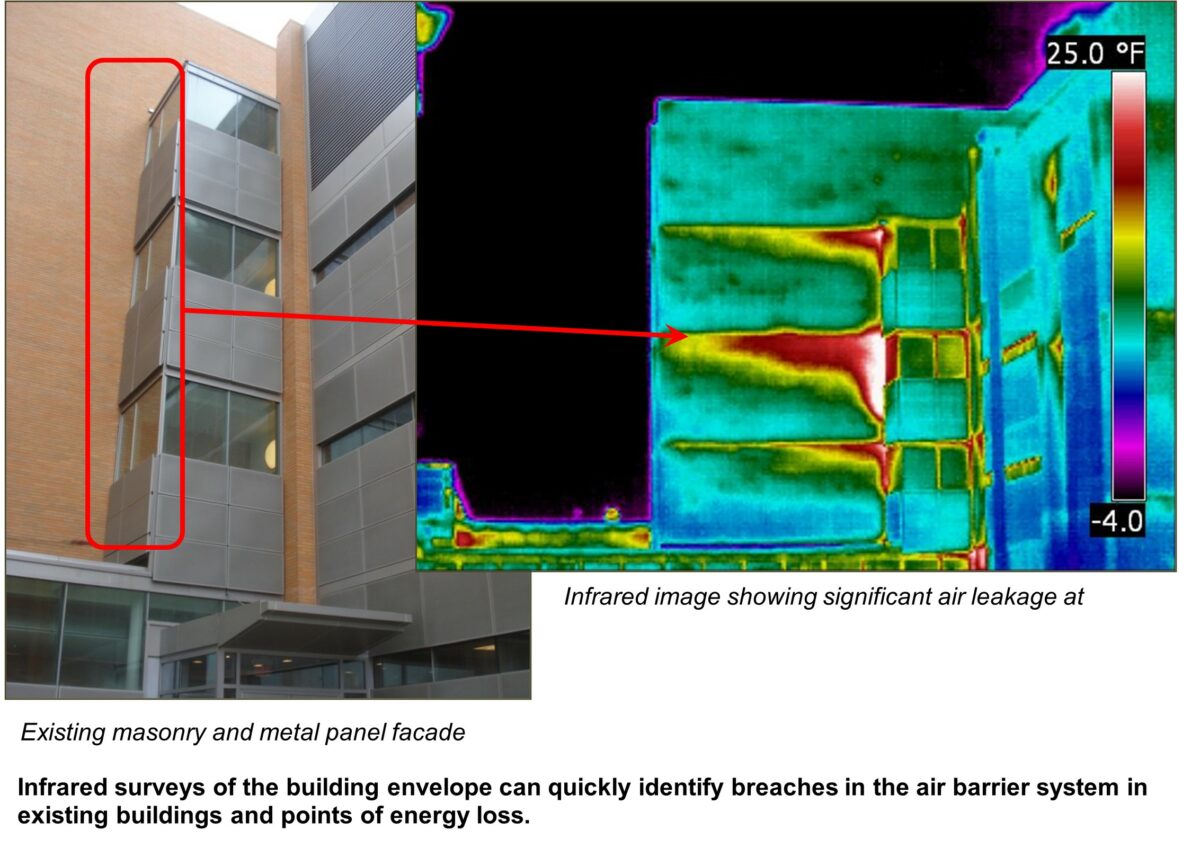

Data acquisition is another tool we often use to aid in evaluation of moisture related issues of a building. Whether evaluating moisture related failures of wall and roof components, renovations and upgrades to existing and historic buildings, or complaints of occupant discomfort, our services generally begin with a field data collection and existing condition assessment. WDP’s experience with data logging and utilization of collection equipment is extensive. We routinely deploy ambient temperature and humidity data loggers to determine the conditions over the course of time both in conditioned spaces and other spaces prone to moisture related or HVAC control issues, such as crawl spaces, basements, attics, and plenums. We also have pressure sensors which can be deployed to verify building pressurization to better assess air leakage or HVAC issues. This information, when used in conjunction with in-situ instrumentation, allows WDP to assess how heat and moisture are being transported through a building holistically and study the impact of interior and exterior conditions on specific building envelope components.

Additionally, we often utilize data acquisition devices as an aid when performing diagnostic water testing to provide an early detection system of moisture migration before bulk water is visually observed. This is a particularly helpful tool for building with historic significance or existing buildings with sensitive interior conditions. The use of in-situ data acquisition allows us to monitor locations within a wall that are not easily accessible and over a period of time when visual observations may not suffice. This approach can also be a valuable tool to assess the migration of moisture vapor that would occur through air barrier defects following a rain event.

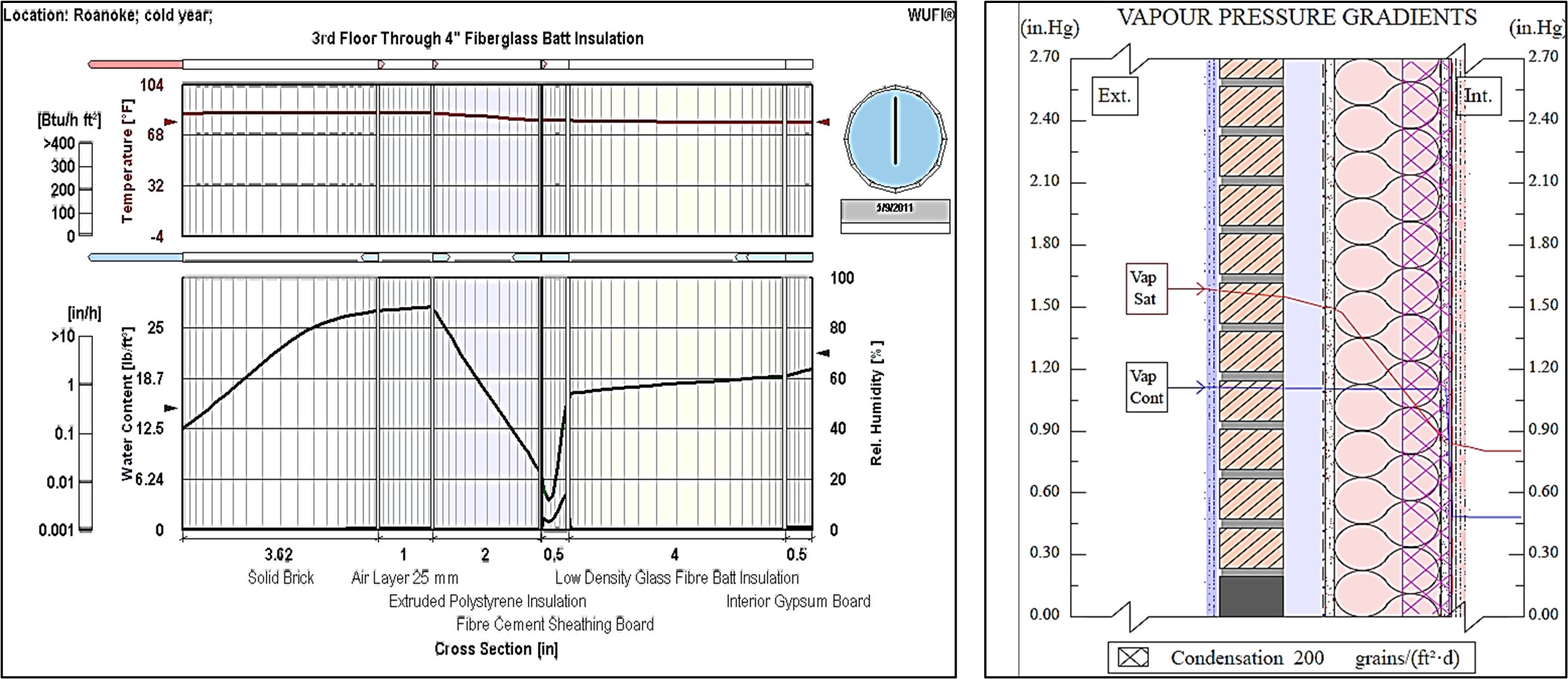

In addition to utilizing this software for ratings of fenestration, THERM can be used to evaluate heat transfer through the fenestration system and surrounding building envelope components in order to evaluate various configurations that would limit thermal bridging at these critical intersections.

Building airtightness is one factor that affects building air change rates under normal conditions of weather and building operation. These air change rates account for a significant portion of the space-conditioning load and affect occupant comfort, indoor air quality, and building durability. The referenced test method produces results that characterize the airtightness of the building envelope. These results can be used to compare the relative airtightness of similar buildings, determine airtightness improvements from retrofit measures applied to an existing building, and predict air leakage. Use of this standard permits the identification of leakage sources and rates of leakage from different components of the same building envelope.

Low-voltage electronic leak detection (ELD) (also known as electric field vector mapping, EFVM) is a method of evaluating a waterproofing or roofing membrane by detecting the variations in electric potential created by defects in the membrane. To perform the test, a test area is encircled by a conducting wire, and the wire is connected to a portable low-voltage power source. Providing an electric current to the conducting wire creates an electric field within the loop when the surface of the membrane is wet. If a defect is present, current will flow through the field of the wet membrane and ground to the structure of the building through the hole. An operator with two probes connected to a voltmeter touches the probes to the membrane surface and can detect that current flow from the electric field to the structure by noting a voltage reading. When the two probes are aligned with a leak, the voltage meter will peak, directing the operator to the leak. The operator will methodically check the entire roof, or specific parts, in this manner.

WDP uses a Buckleys WR10 Wet Roof Leak Detector kit, which was specifically designed to perform this electronic leak detection (ELD) testing.

The test method can be used on the following roof materials:

- TPO

- PVC

- KEE/Elvaloy

- modified bitumen

- built-up roofs

- hot fluid-applied rubberized asphalt

- cold-applied liquid membranes